2026-01-21

2026-01-20

2025-12-26

2025-09-30

2025-06-24

2025-06-13

Address: 6th Floor, No. 205-3, Section 3, Beixin Road, Xindian District, New Taipei City

Phone: +886-2-89131997

Fax: +886-980503633

Email: info@sg.com.tw

Address: West 3rd Floor, China Steel Tower, Building M-7, Majiaoling Industrial Zone, High-tech Zone, Nanshan District, Shenzhen

Phone: 0755-2697 1006

Fax: 18002554660

Email: sales@acroview.com

Author: System Generalrelease date:2020-11-20Viewers:3066

As a leading programmer manufacturer in the industry, Angke Technology (stock code: 873207) has taken the lead in in-depth cooperation with the domestic excellent chip manufacturer Allwinner Technology. The company has adopted the AP8000 manual burner and high-quality automatic burner IPS7000 with high cost performance. EAP3000 and EAP5000 fully support the programming algorithms of Allwinner (Corelink Wireless) MCU chips XR809 and XR871;

Since its establishment, Chiplink, a subsidiary of Allwinner Technology Group, has successively launched WiFi connection chip XR819, low-power wireless MCU chip XR871, WiFi+BT combo chip XR829, IOT WiFi chip XR809 and high-performance 32bit MCU XR32F4, of which XR809 Both XR871 and XR871 have passed the Alibaba Cloud loT technology certification.

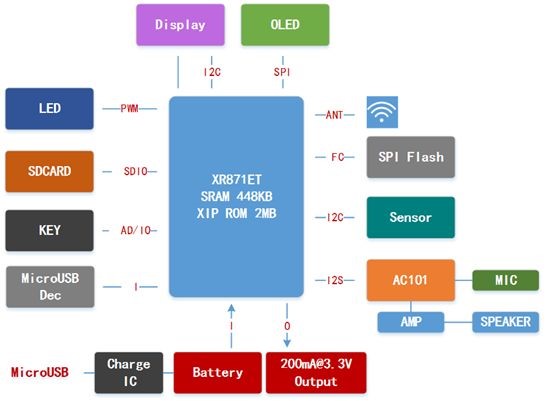

The hardware part of the story machine solution adopts the XR871ET+AC101 package form to create a highly integrated and cost-effective audio solution. XR871ET uses its high-performance CPU and abundant RAM resources to realize audio broadcast control, MP3 decoding and ARM/Speex encoding functions, and realizes a complete solution of single/dual microphone, mono/stereo and karaoke functions through AC101 Audio Codec; At the same time, based on the rich peripheral interfaces of XR871ET, the story machine solution realizes the direct expansion of many functions such as power supply, SD card, ear lights, eye lights, keys, etc. without adding additional costs, showing super high integration and streamlined The system design has laid a solid foundation for the high cost performance and high stability of the whole system.

图一:XR871ET故事机系统

Figure 2: Story machine software system

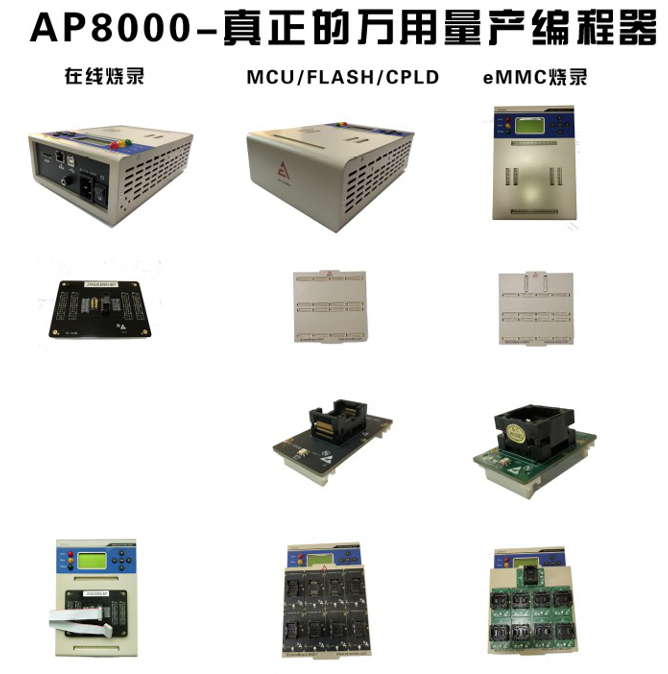

The AP8000 programming platform is the first to support the one-to-eight programming mode, and the previous on-board programming mode of Allwinner SPI NAND has been increased from 240UPH to 1200UPH, which greatly reduces production personnel;

Picture 3: AP8000

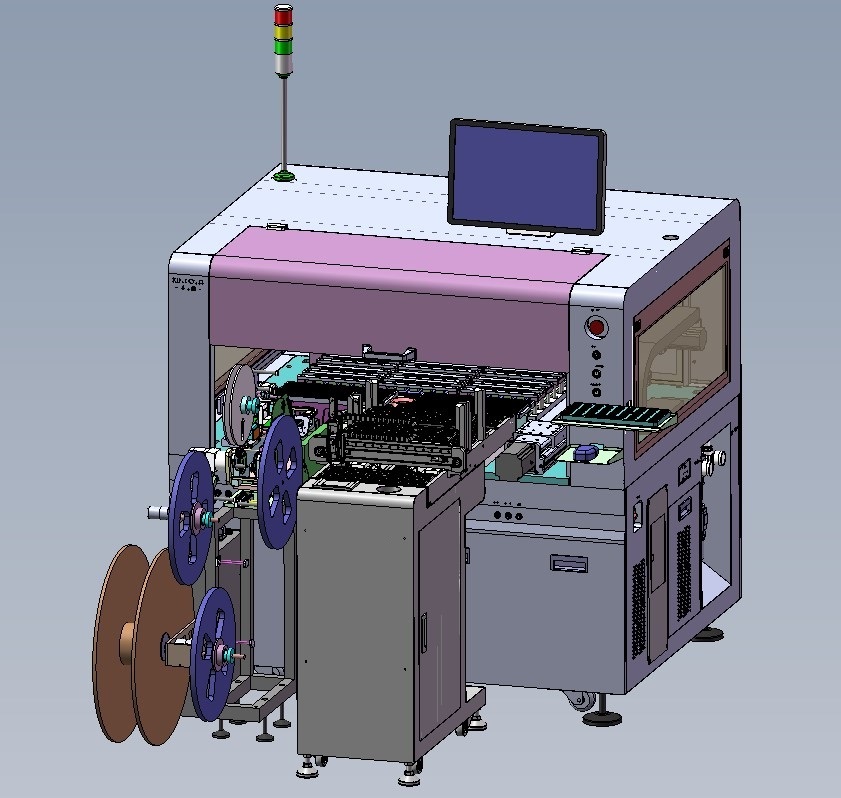

Acroview cost-effective automation equipment EAP3000 and EAP5000 series have been optimized for all Nand Flash programming in Allwinner's story machine solution, and the efficiency has been greatly improved;

Acroviewtech EAP3000 automatic burner

Picture 4: EAP3000

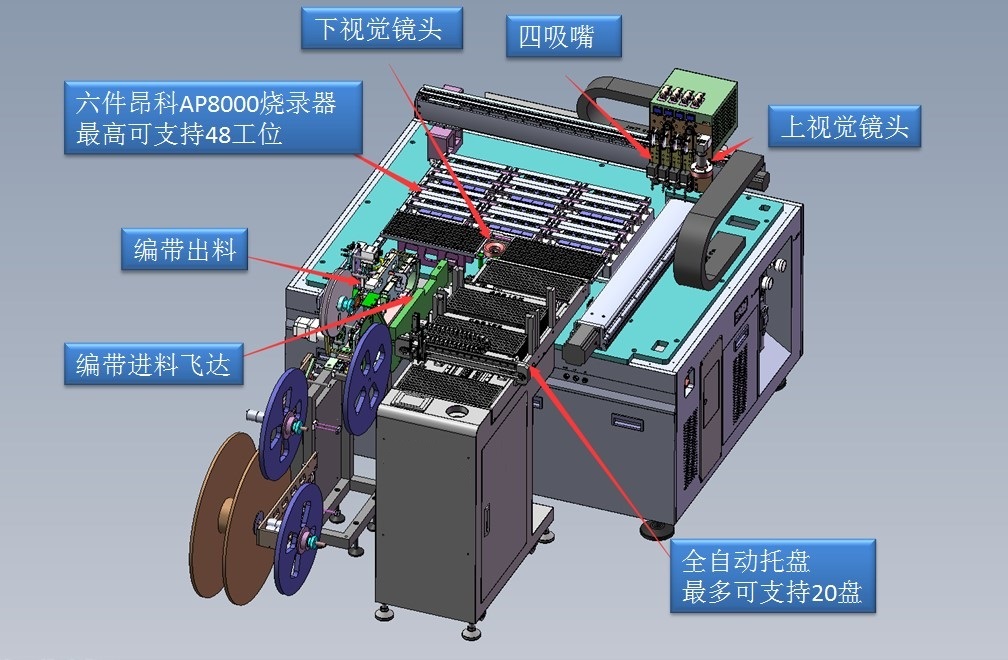

Acroviewtech EAP5000 automatic burner

Picture 5:EAP5000

Figure 6: EAP5000 section view

High performance/price ratio

Based on the WIN7 system operation interface, it supports two working modes: tape in, tape out, and tray in and out. Single nozzle or double nozzle or four nozzles are optional. The nozzle has a rotating function and can burn 1~48 ICs at the same time. ICs within 30 seconds can produce 800~1800UPH per hour (actual production capacity, non Theoretical value) CCD assisted positioning, automatic rejection of defective products. To burn different ICs, you only need to replace the corresponding burn socket and burner, and one person can operate 4~10 machines.

Taping & Tray Device

The braid is newly upgraded, the feeding tape size can be 8mm-32mm, and the operation is simple and convenient. The tray uses AutoTray, which can load 20 trays at a time, saving labor and time.

Up and down CCD auxiliary positioning function (optional)

With high-pixel CCD module to assist the coordinate adjustment of each operating point, the coordinate adjustment is precise, accurate and fast

Print job

For both tape and pallet packaging, automatic dot printing before IC sealing and packaging is provided.

Acroviewtech (stock code: 873207) is the first domestic listed company in the burner (programmer) industry, independently owns the R&D, production and service of burner (programmer), automatic burner and automatic online burner At the same time, it has established R&D and production service bases in Shenzhen, Taipei, Suzhou, Yangzhou, and Shanghai. It is the preferred brand of programming solutions for large factories at home and abroad. Acroviewtech has more than 10 years of rich experience in the development, manufacturing and service of programming equipment Experience, world-leading technology, and is committed to providing customers with innovative programming solutions and products. We are working hard to make outstanding contributions to the reliability, security and intellectual property protection of programming equipment. Acroview has always firmly believed that the pursuit of quality and technology will make more and more electronics manufacturers choose Acroview as their trusted partner. New products are continuously being released, please stay tuned.

System General Limited

Address:6F,No.205-3, Sec.3, Beixin Rd., Xindian Dist.,New Taipei City 23143, Taiwan

TEL: +886-2-89131997

Fax: +886-980503633

Email: info@sg.com.tw

Acroview Technology Co.,Ltd.

Address:3F , Blg 7 West, Sinosteel Building, Maque Industry VillageNanshan, Shenzhen, 518057, Guangdong

TEL:+ 86 075526971006

Mobile phone:18002554660

Email:sales@acroview.com

Copyright ©2019-2022 Core Micro Semiconductor (Suzhou) Co., Ltd.苏ICP备2022007532号-1